RF, Microwave, and Wireless

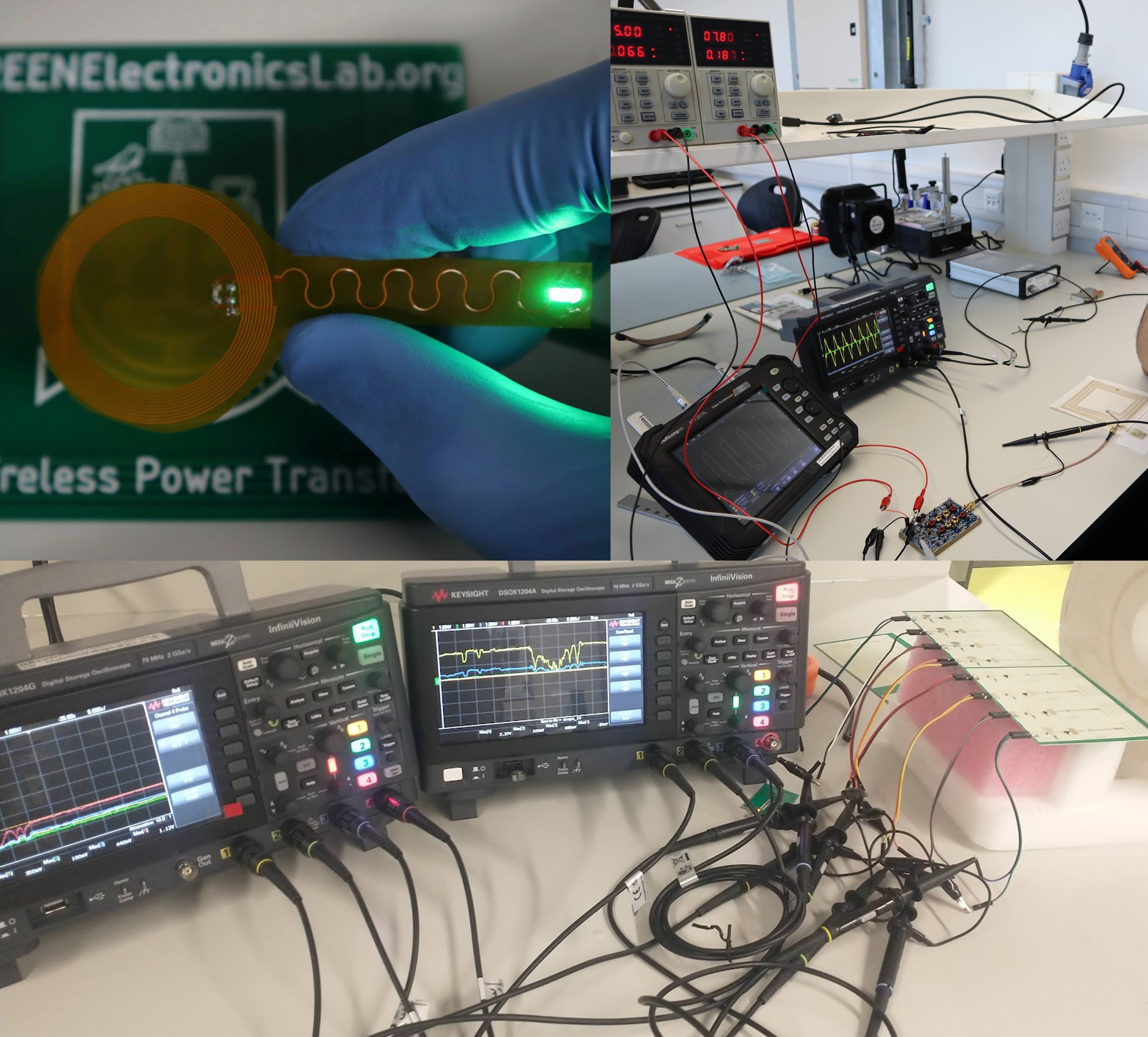

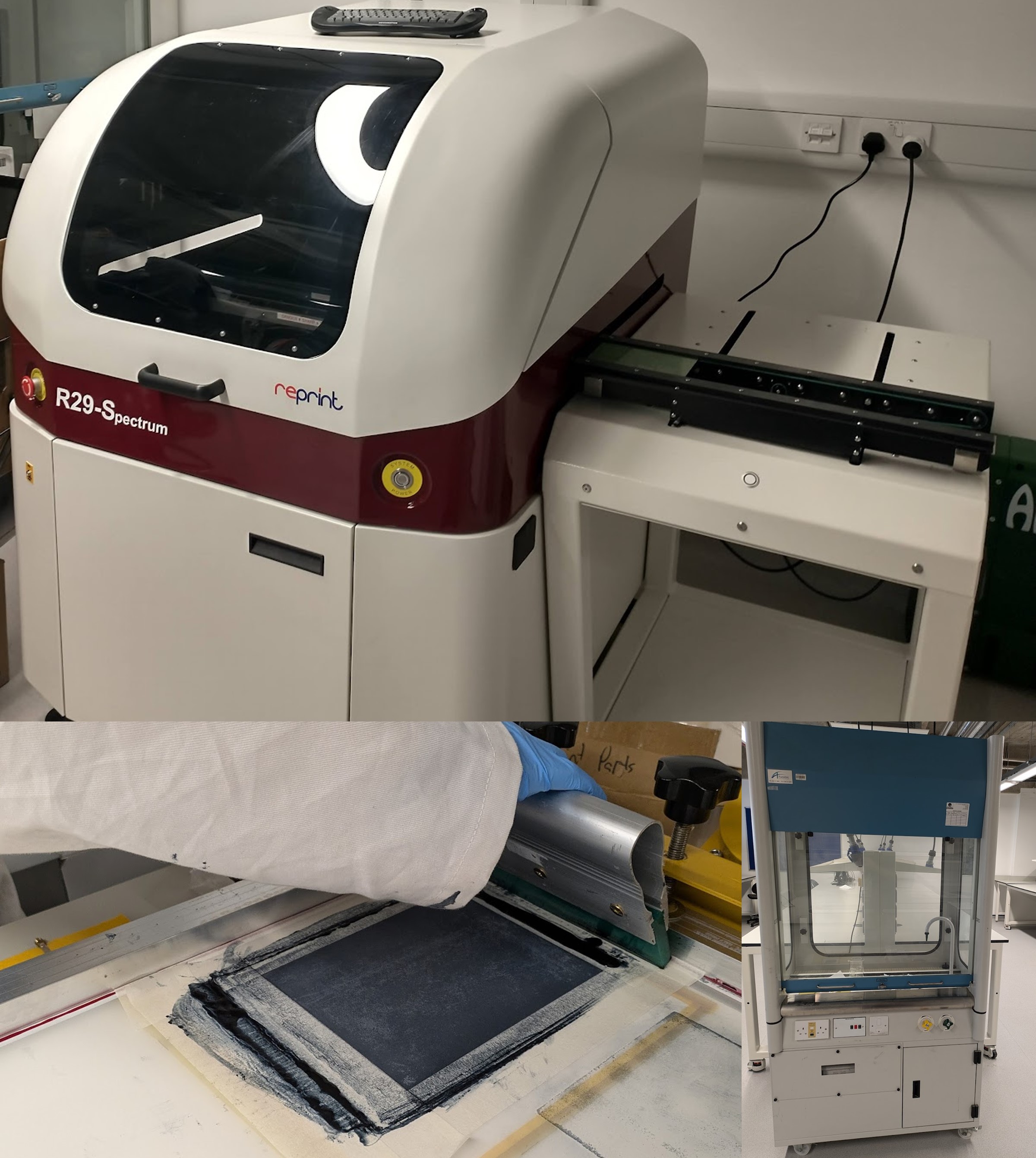

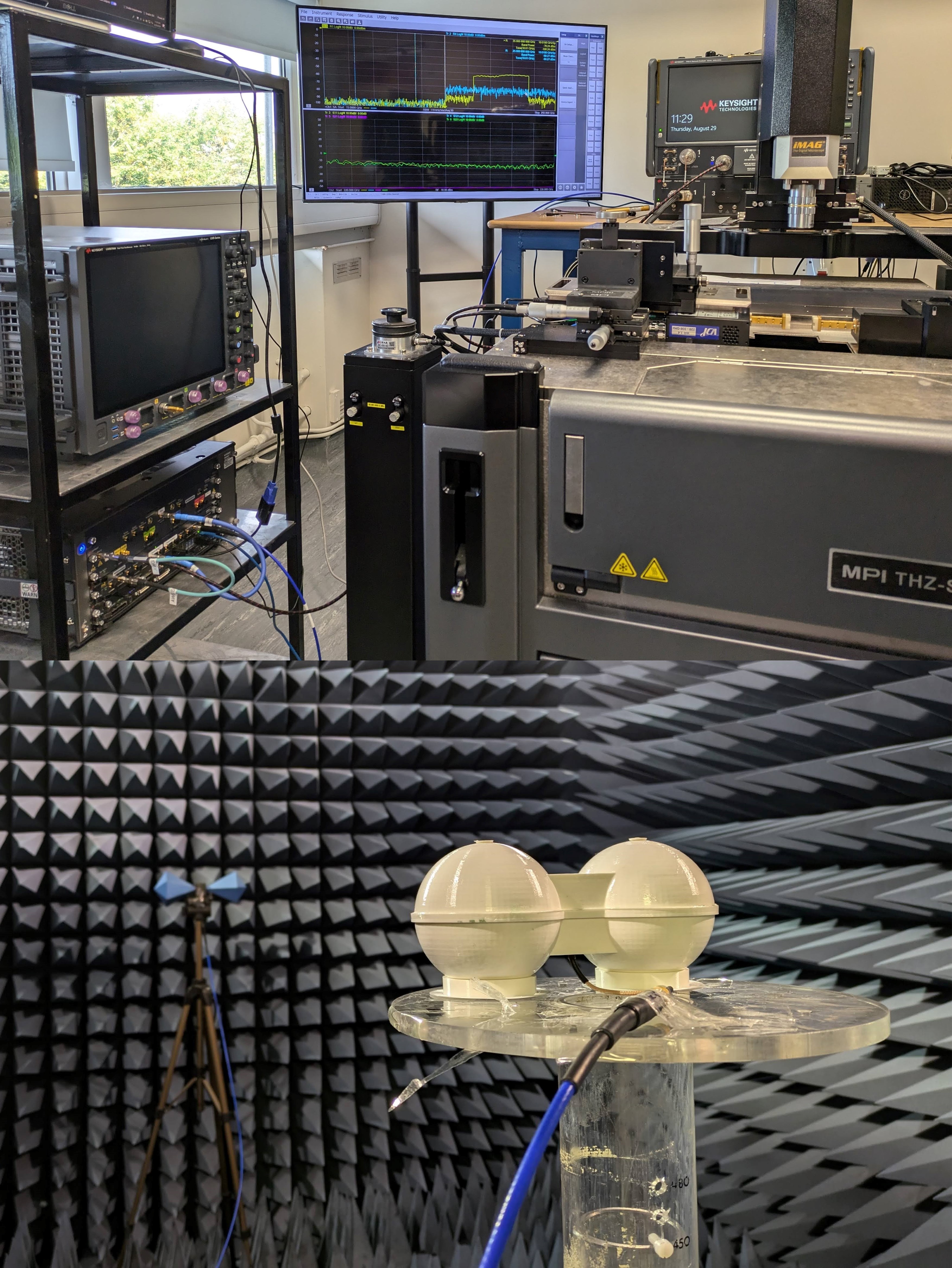

We have dedicated and automated equipment for in-situ RF measurements, including unconventional devices/sensors (refer to the shared equipment section for mmWave/THz facilities).

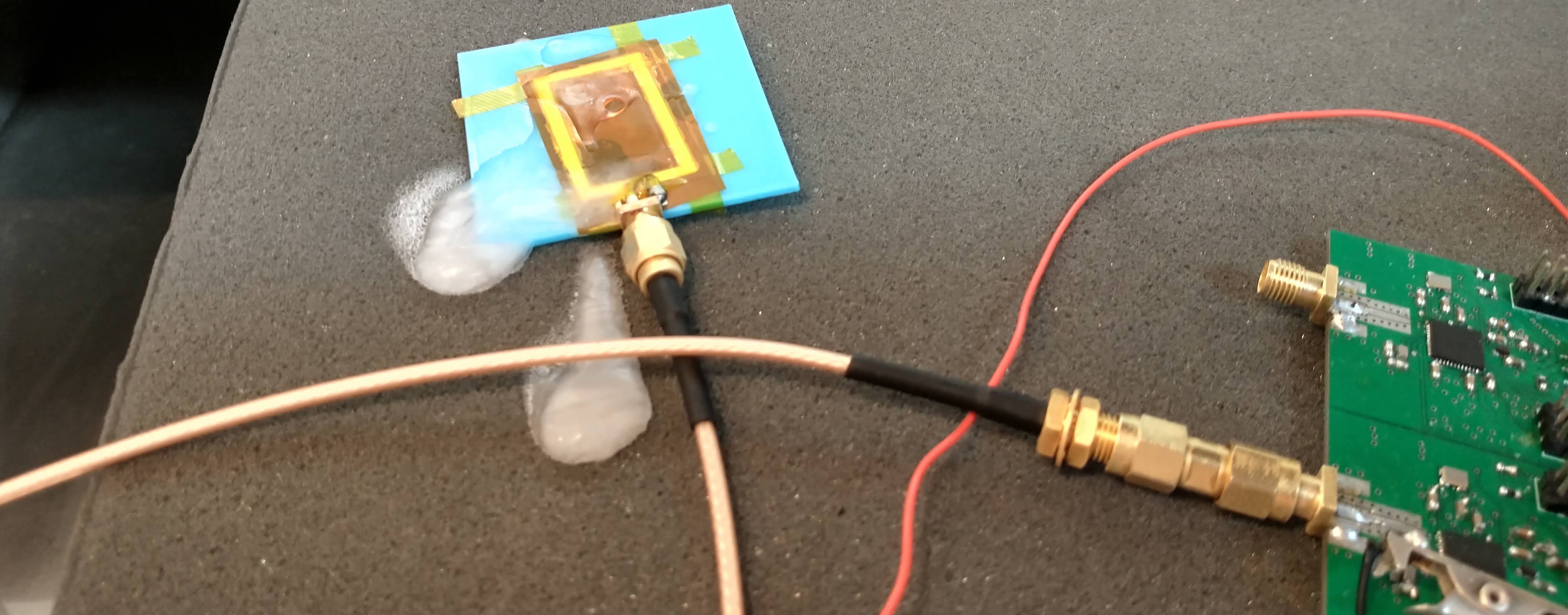

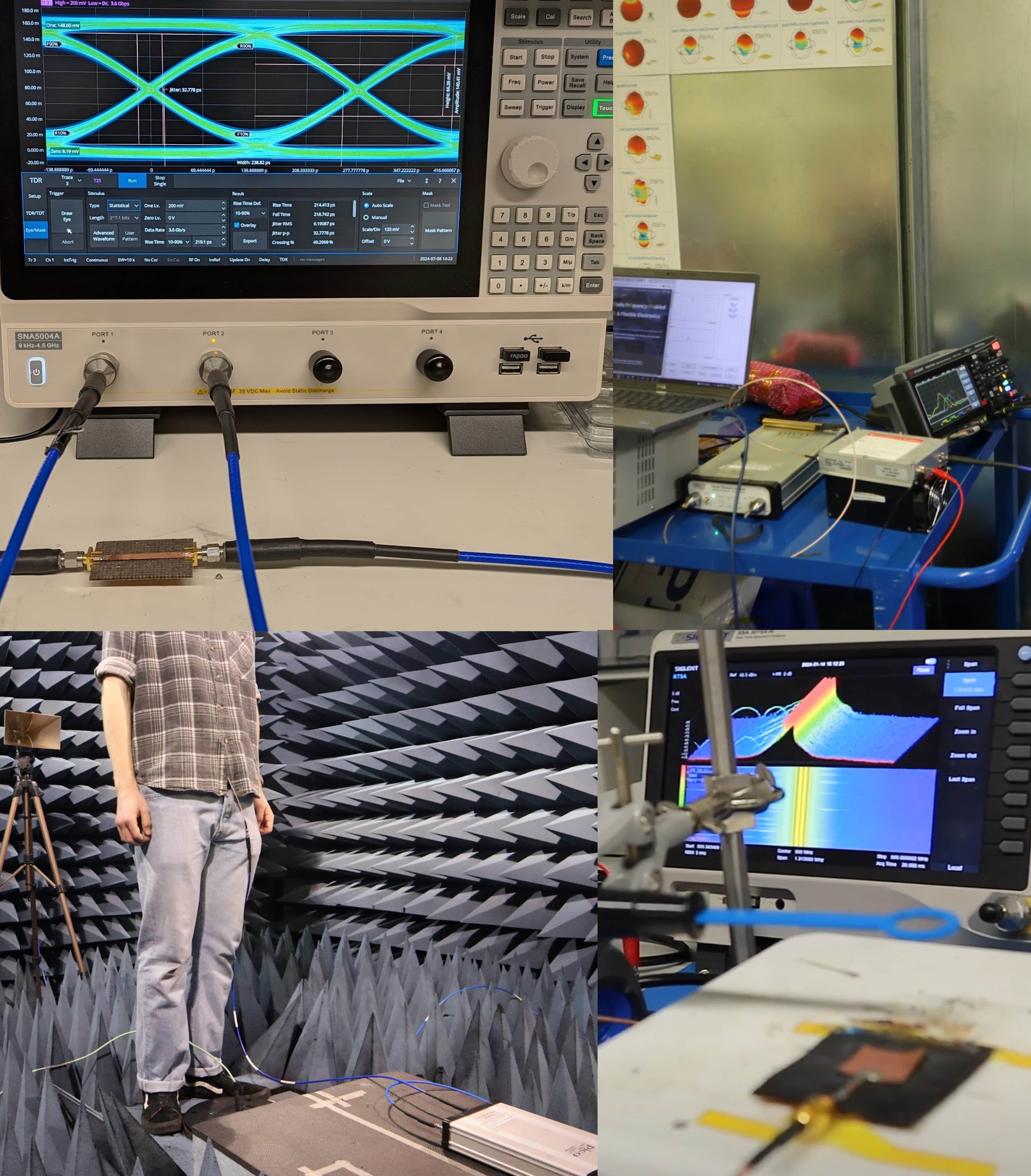

• Multiple Vector Network Analyzers (VNAs) including 2-port (300 kHz to 6/7.5 GHz) and 4-port systems (9 kHz to 4.5 GHz), and compact/portable VNAs for in-situ sensor and antenna measurements

• Real-time spectrum analysis up to 7.5 GHz (40 MHz RT bandwidth).

• Time-domain reflectometry (TDR), eye diagrams and signal integrity measurements (4.5 GHz/>GBPS).

• Multiple dual-ridge horn antennas 0.7-8+ GHz, and other CP/LP reference antennas.

• UHF RFID readers, providing RSSI and phase data in the US/EU bands.

• 15+ portable NanoVNAs for paralellized testing of sensors (100 kHz to 500 MHz).

• Material characterization (permittivity and loss-tangent) from under 1 MHz to 1+ GHz.